Benefits of Injection Moulding (Rubber)

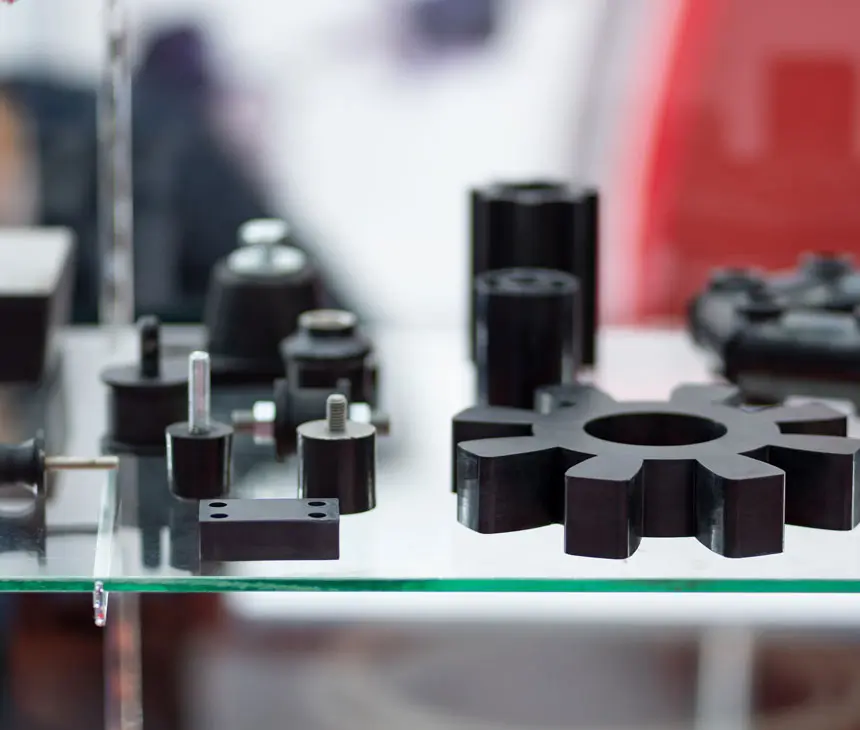

Once the moulds have been designed and produced, the benefits of using injection moulding to produce rubber components are many and varied. These benefits and, indeed, disadvantages, should all be carefully considered before selecting injection moulding over compression moulding. 1. As with compression moulding, the design and manufacture of the moulds themselves can be a […]

Compression v Injection

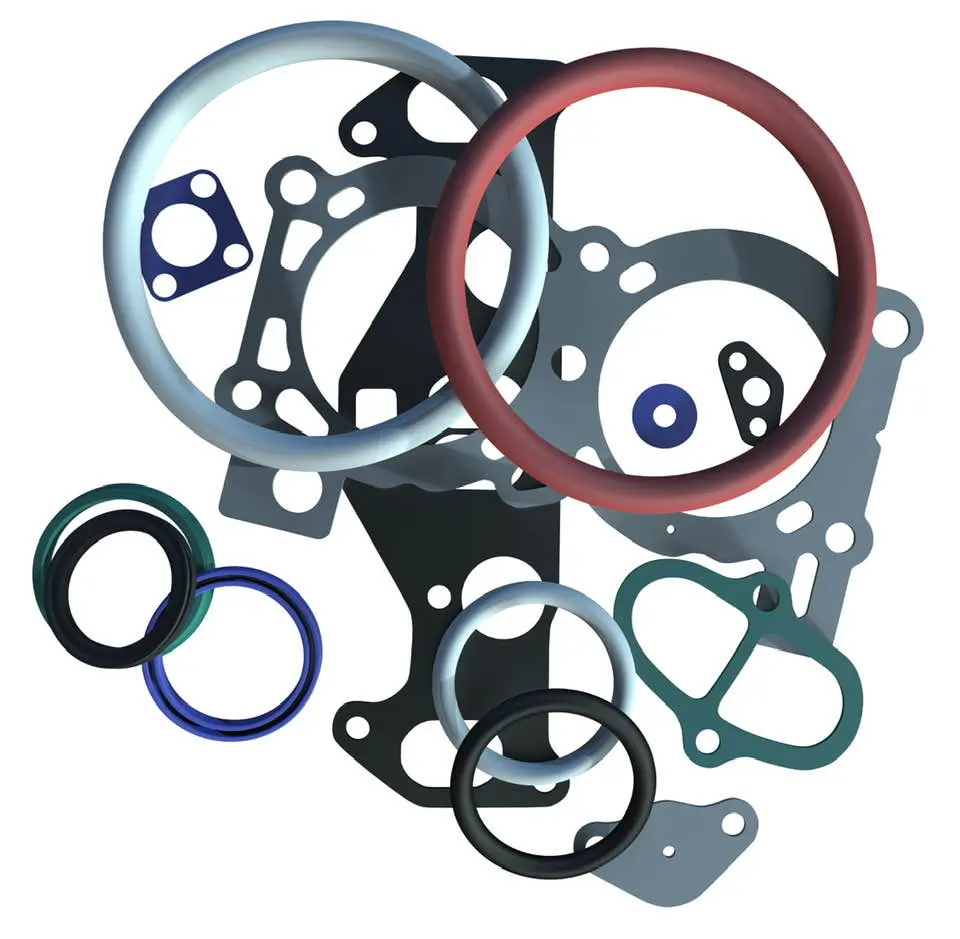

Compression Moulding v Injection Moulding Injection rubber moulding is better suited to high volume production whereas compression rubber moulding is better suited to pliable and flexible materials and has cheaper tooling costs. Compression Moulding Compression moulding is a process that’s defined by its use of pressure and heat. AT MACH Rubber the EPDM is placed […]

Latest Trends in Rubber Moulding Technology

In the dynamic realm of manufacturing, the rubber moulding industry stands at the forefront of innovation. In this article, we delve into the latest trends reshaping the rubber moulding landscape, uncovering transformative changes that promise to redefine the industry’s future. Industry 4.0 and Smart Manufacturing: Transforming Rubber Moulding Processes The infusion of Industry 4.0 principles […]