Compression Moulding

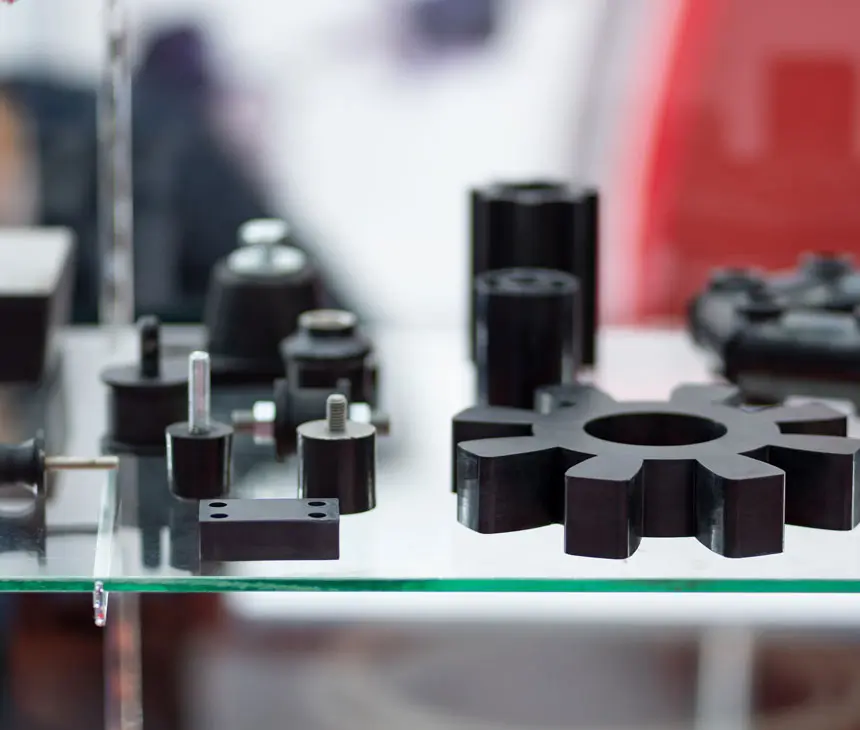

Discover innovation with MACH Compression Rubber Mouldings. Precision-crafted rubber components for diverse industries, ensuring quality and reliability.

Rubber Mould Manufacture

As specialist rubber moulding manufacturers, MACH Rubber provides mouldings to each customer’s exact specifications. We manufacture compression moulding using a range of materials, including natural rubber, FKM/Fluoroelastomer, neoprene and EPDM.

Items we can manufacture include rubber seals, rubber buffers, dust caps, rubber bushes and gaskets. All our mouldings are manufactured with each client’s individual needs in mind and to your exact specifications, ensuring our clients are always satisfied with the finished product.

If you’d like to know more about our work, or if you’d like a free quote on any of our manufacturing services, contact MACH Rubber today using the enquiry form below.

Compression Moulding

Compression moulding is a process that’s defined by its use of pressure and heat. AT MACH Rubber the EPDM is placed inside the mould cavity where it’s heated. When the rubber is exposed to both heat and pressure, it cures inside the mould, so forming the product or component.

Compression moulding is a low-cost moulding process that’s ideal for large-volume manufacturing applications. Compression moulding also supports a wide variety of shapes and sizes. It can be used to create objects with thin or thick walls in a wide range of shapes.

One drawback of compression moulding is the need for manual trimming of excess material in order to produce the finished component.

Can’t find what you’re looking for?

Injection or Compression Moulding? Which is best for you? Contact us today to discuss your requirements and we will provide a free, no-obligation quote.

Download Our Company Brochure

Please enter your name and email to access our company eBrochure.