Compression Moulding v Injection Moulding

Injection rubber moulding is better suited to high volume production whereas compression rubber moulding is better suited to pliable and flexible materials and has cheaper tooling costs.

Compression Moulding

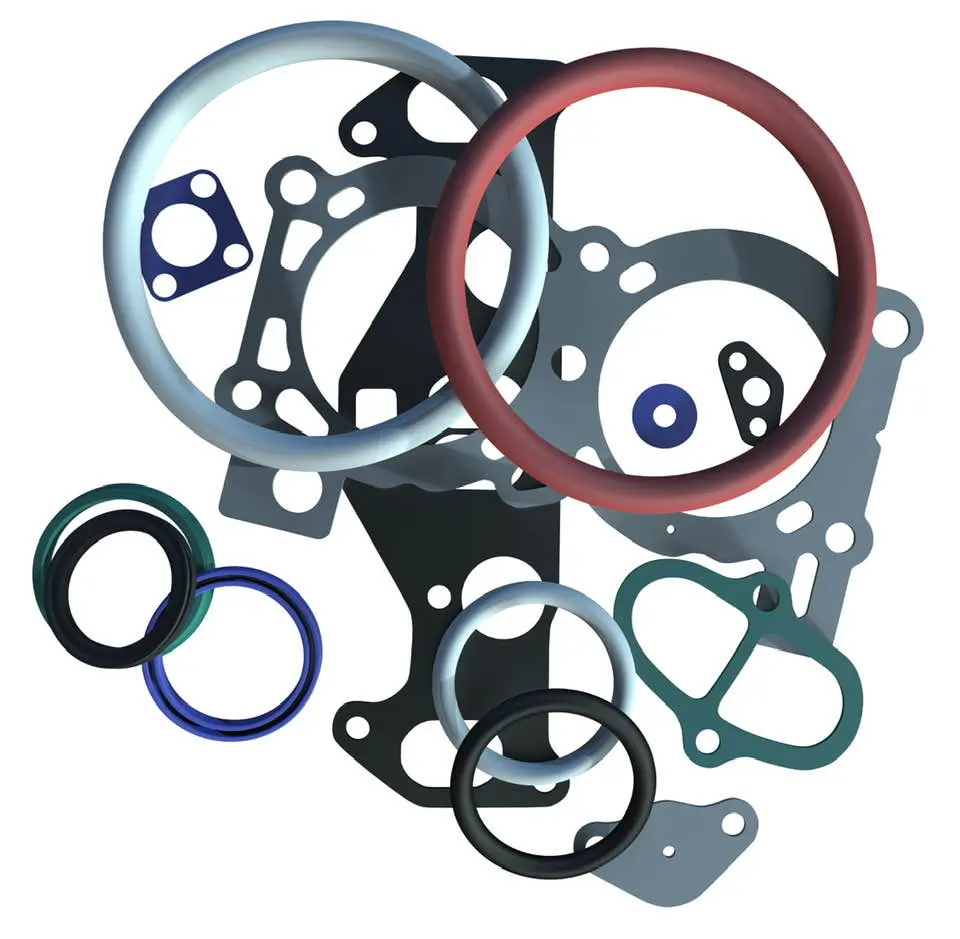

Compression moulding is a process that’s defined by its use of pressure and heat. AT MACH Rubber the EPDM is placed inside the mould cavity where it’s heated. When the rubber is exposed to both heat and pressure, it cures inside the mould, so forming the product or component.

Injection Moulding

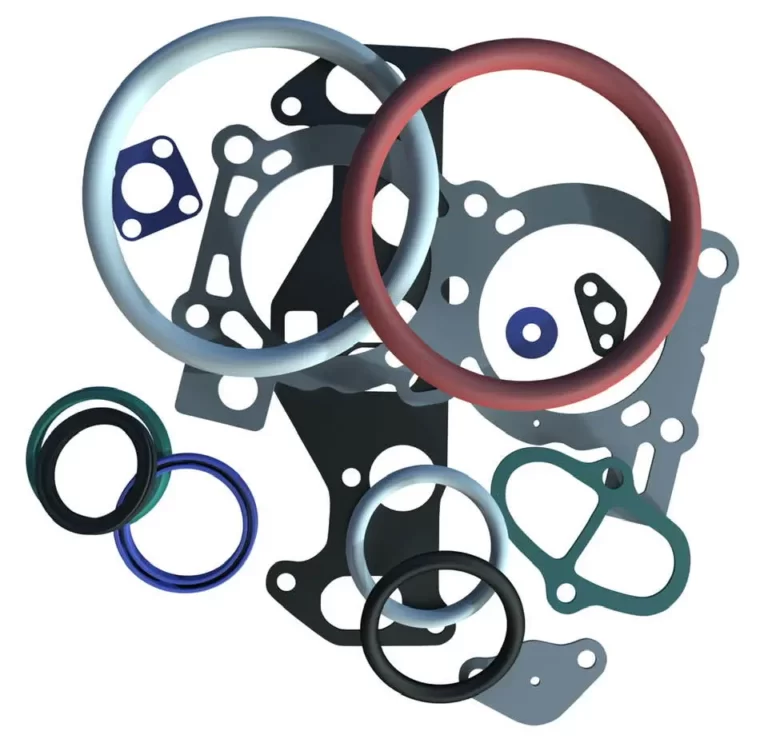

Injection moulding, as the term suggests, involves injection technology. The raw material is injected into a mould cavity and, under heat and pressure, takes the form of the mould itself.

The Benefits of Compression Moulding

Compression moulding is a low-cost moulding process that’s ideal for large-volume manufacturing applications. Compression moulding also supports a wide variety of shapes and sizes. It can be used to create objects with thin or thick walls in a wide range of shapes.

One drawback of compression moulding is the need for manual trimming of excess material in order to produce the finished component.

The Benefits of Injection Moulding

Injection moulding allows for the fast and efficient production of uniform objects. Since both the pressure and heat can be precisely controlled, MACH Rubber can quickly produce many objects of the same shape and size.

Injection moulding does away with the need for manual trimming and produces less waste.